The Difference Between Full Process and Semi-Process in Textile Processing

- Share

- publisher

- OD

- Issue Time

- Jul 21,2025

Summary

The semi-process involves limited pre-treatment steps, often leading to uneven dyeing, lower color saturation, and reduced durability, which may disappoint consumers. The full process encompasses every necessary step, including pre-treatment, dyeing, printing, and finishing, resulting in vibrant colors, enhanced durability, and improved aesthetics. Key techniques like singeing and mercerizing further elevate the quality of textiles produced through the full process.

The Difference Between Full Process and Semi-Process in Textile Processing

In the world of textile manufacturing, the processes applied to fabrics can significantly influence the quality, aesthetics, and durability of the end products. Two primary processing methods dominate this industry: the semi-process (半工艺) and the full process (全工艺). Understanding these methods is crucial for manufacturers seeking to optimize their production techniques and meet consumer demands. This article will delve into the definitions, methodologies, advantages, and drawbacks of both processing techniques, emphasizing the significance of full processing in delivering superior textile products.

Semi-Process in Textile Processing

The full process represents a comprehensive approach to textile manufacturing, involving every necessary step to ensure high-quality results. This method encompasses stages such as pre-treatment, dyeing, printing, setting, and finishing. Each phase plays a crucial role in enhancing the fabric's characteristics. Specifically, pre-treatment processes prepare the fabric for dye application, ensuring that dyes adhere properly and evenly. The dyeing phase itself allows for deeper, more vibrant colors, which are uniformly distributed across the fabric. By integrating printing and finishing techniques, full processing not only improves the aesthetic appeal of the textiles but also significantly enhances their durability and resistance to color fading. As a result, products manufactured using the full process tend to meet higher standards of quality, promoting consumer satisfaction.

Key Techniques in Full Processing: Singeing and Mercerizing

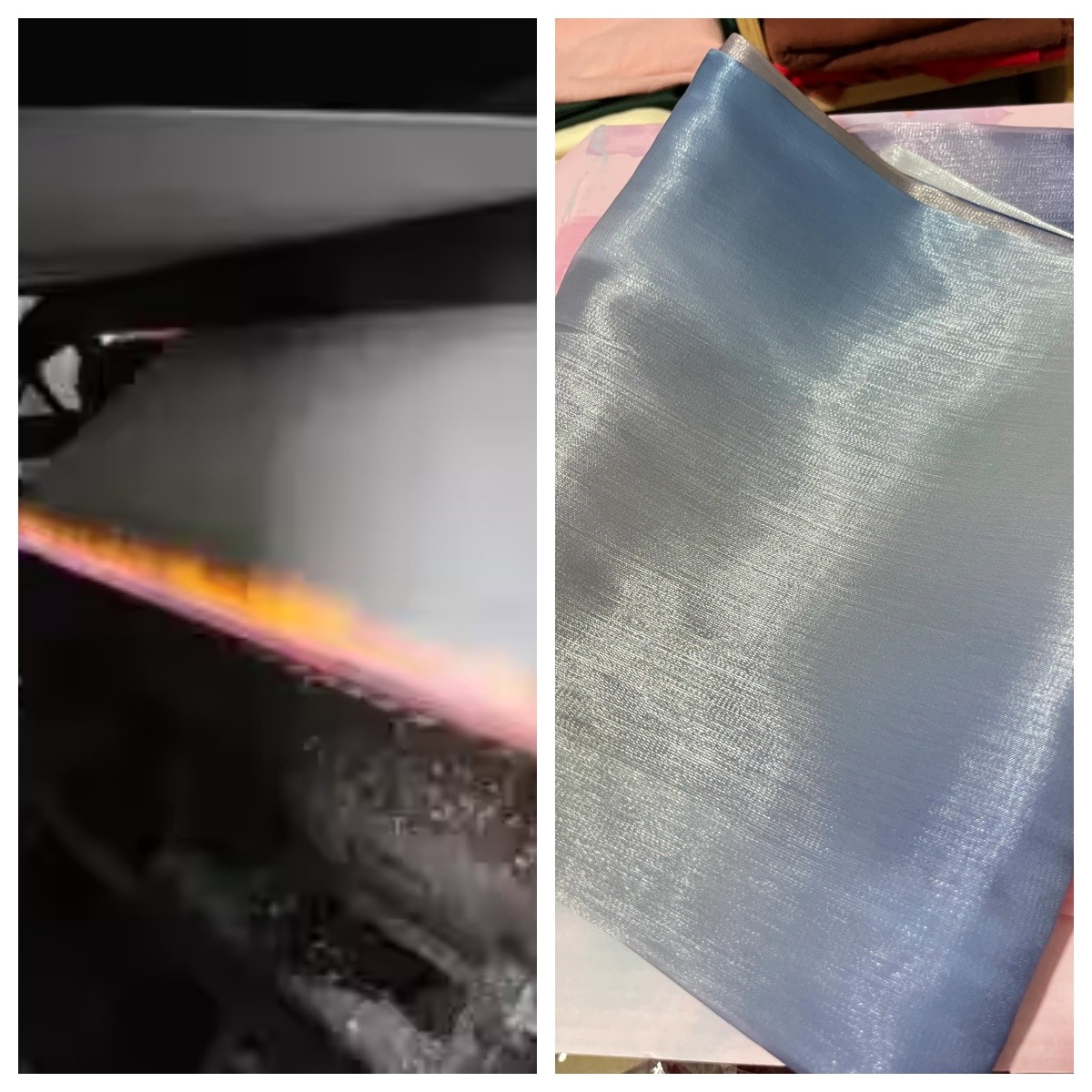

Two critical techniques employed in the full-processing workflow are singeing and mercerizing. Singeing involves using high temperatures and chemical agents to burn off unwanted fibers from the fabric’s surface, achieving a smoother finish. This process not only enhances the fabric’s appearance but also improves its performance by reducing pilling and the potential for dirt retention.

On the other hand, mercerizing (丝光) is a chemical treatment applied after the fabric is woven, which transforms the texture by making the surface smoother and shinier. This treatment significantly boosts color vibrancy, enhances dye uptake, and imparts a soft, luxurious feel to the fabric. The advantages of these techniques are often diminished in semi-processing methods, which typically skip these critical steps. As a result, textiles produced with full processing exhibit superior quality and aesthetic appeal compared to their semi-processed counterparts.

Conclusion

The comparison between semi-process and full process textile manufacturing reveals essential insights regarding quality and consumer satisfaction in the textile industry. While semi-processing can offer certain cost advantages, the benefits of full processing—ranging from uniform dyeing to enhanced durability and aesthetics—make it the preferred choice for many manufacturers aiming to deliver high-quality products. As the textile industry continues to evolve, embracing technological advancements and innovative processing techniques will only bolster the capabilities of full processing. Ultimately, manufacturers must carefully consider their processing methods to meet the growing expectations of consumers seeking both quality and longevity in their fabric choices. Through this understanding, the significance of choosing the right processing technique becomes clear, guiding manufacturers towards producing textiles that truly resonate with quality-conscious consumers.